Leading Shot Blasting Machine Manufacturer In China – 30+ Years of Experience

PRODUCTS ON SALE

Shot Blasting Machine For Sale – Major Types

Explore our range of high-performance SBMM shot blasting equipment for sale, engineered for superior cleaning, descaling, and surface preparation. Ideal for enhancing component durability and productivity in metalworking, foundry, and automotive industries, our reliable equipment delivers exceptional results for various applications.

PRICE RANGE

Shot Blasting Machine Price

Shot blasting machine pricing is highly variable, typically ranging from 5,000 for basic manual or portable units to over 100,000 for large-scale, automated industrial systems.

Key factors influencing cost include the machine type (e.g., tumble blasters, roller conveyor systems, or pass-through designs), size and capacity, level of automation (manual vs. PLC-controlled), and specific features such as dust recovery systems or abrasive recycling efficiency.

Additionally, customization for specialized applications (e.g., H-beams, pipes, or delicate components) and compliance certifications (CE, ISO) can further impact the overall investment. For precise pricing, manufacturers typically require detailed project specifications, including material type, desired surface finish, and production throughput

FACTORY SALE, QUALITY MACHINE

Shot blasting Machine to Buy – Types to Choose

As a professional shot blasting machine manufacturer based in China, we integrate R&D, production, sales, and after-sales support to deliver end-to-end shot blasting machine solutions. Whether you’re searching for a standard unit or a customized shot blasting machine, we offer tailored options to match specific industrial requirements.

Our blasting shot machine for sale comes with direct factory pricing, as well as advanced technology, ensuring high quality and a competitive shot blasting machine price.

As a trusted shot blasting machine supplier, we provide transparent wholesale shot blasting machine pricelist and detailed shot blasting machine quotes for global clients, including those looking for shot blasting machine near me in regions like the UK. We have shot blasting machine in-stock to meet urgent needs.

Choose reliability, customization, and value—straight from the shot blasting machine factory.

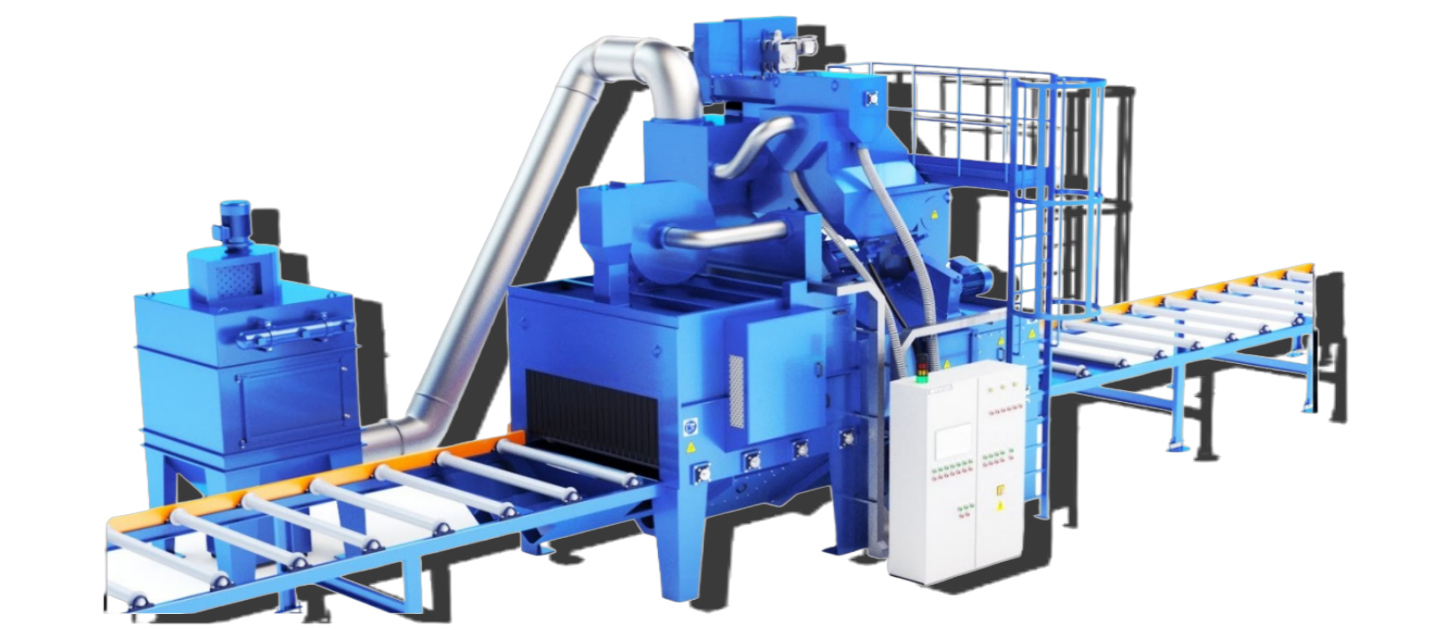

Automatic & Continuous

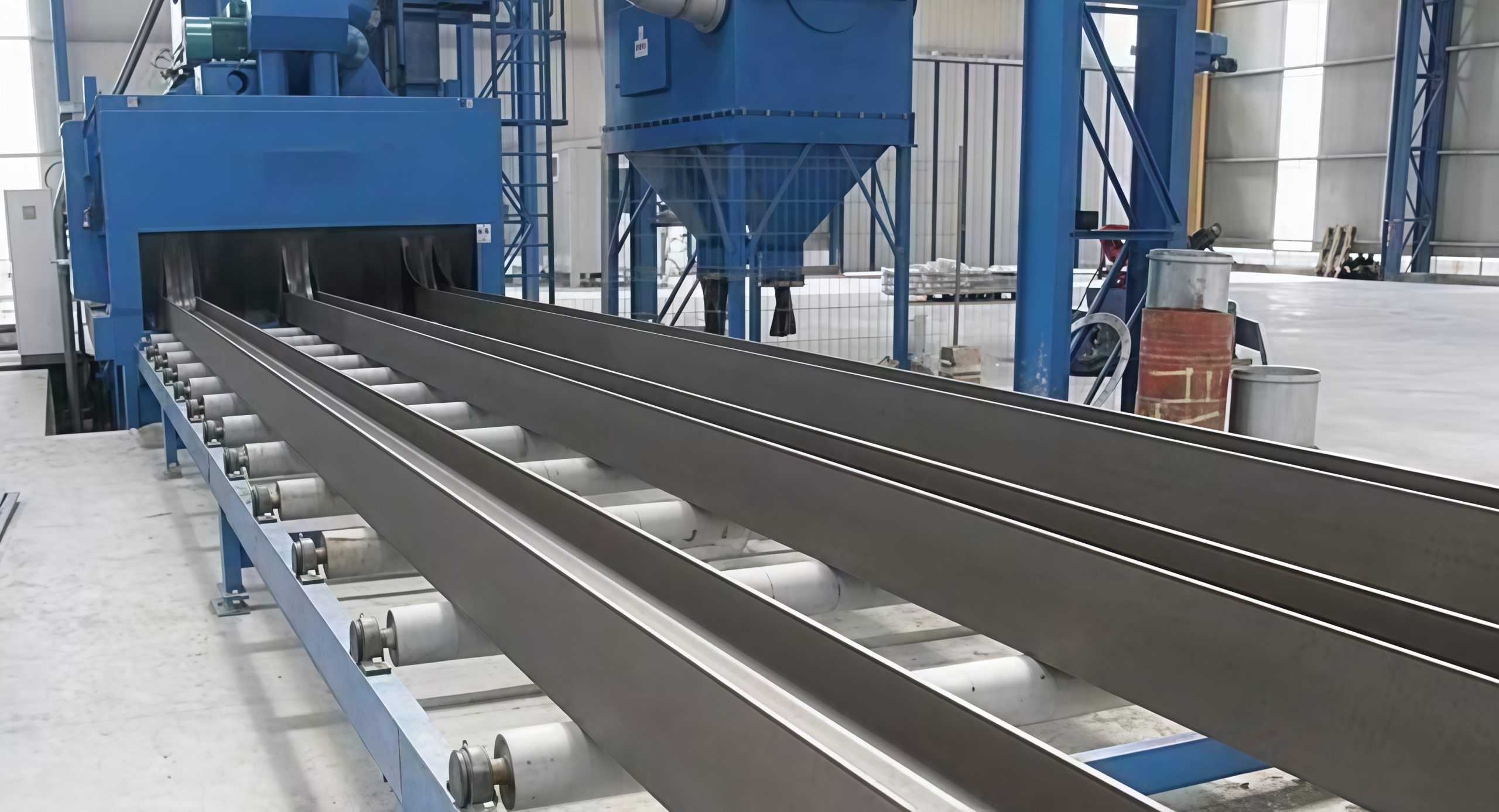

Roller Conveyor Shot Blasting Machine

Inlet width: 1600-4300mm

Inlet height: 550mm

Suitable for cleaning Steel Beam, just like H Beam, I Beam etc.

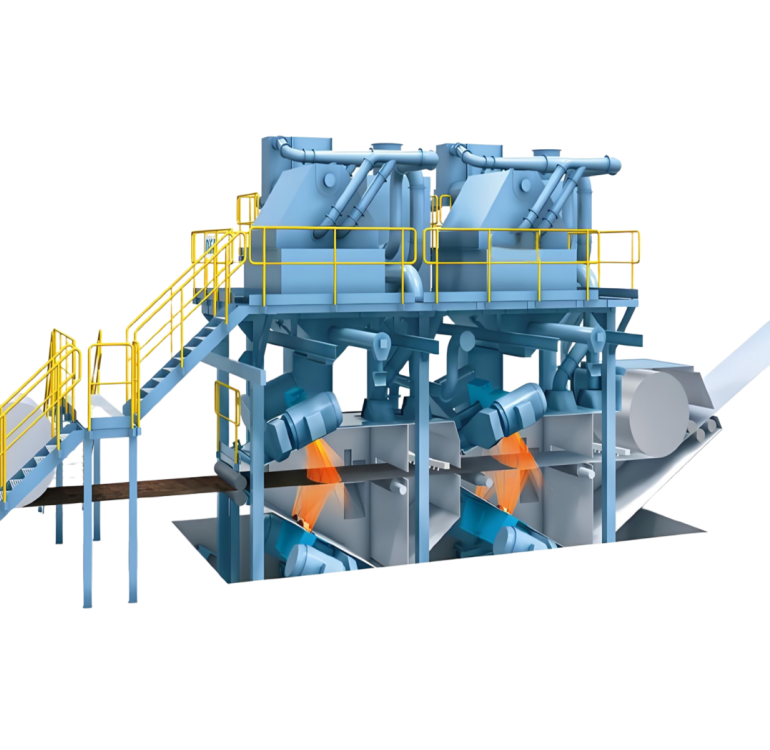

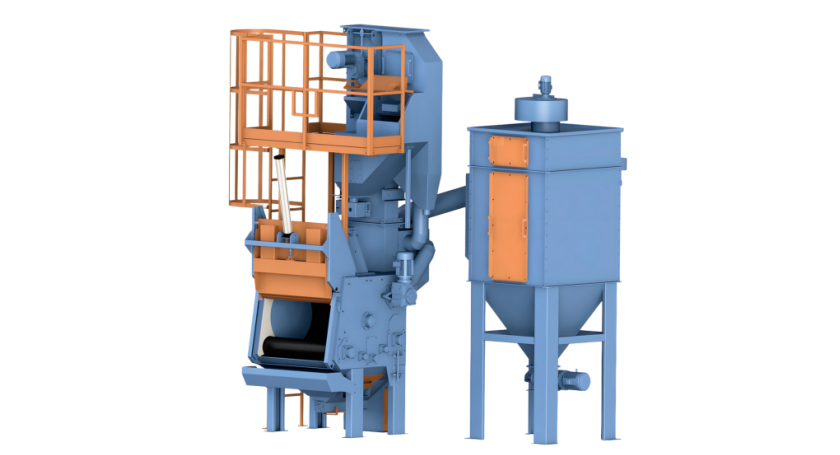

Compact Design

Apron/ Crawler Type Shot Blasting Machine

Productivity: 0.6-5t/h

Feeding amount: 220-1000kg

Suitable for sand removal, rust removal, oxidation skin removal etc.

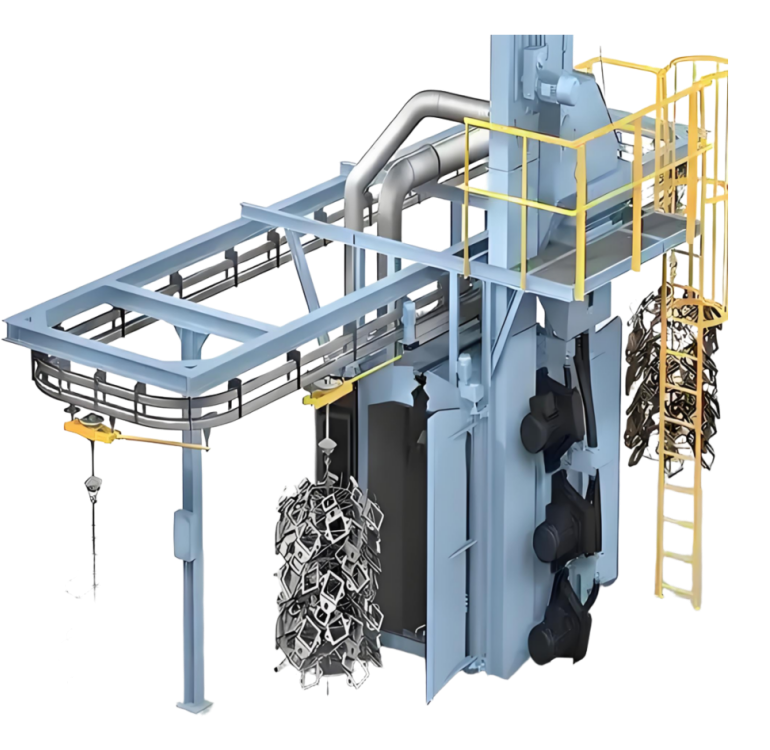

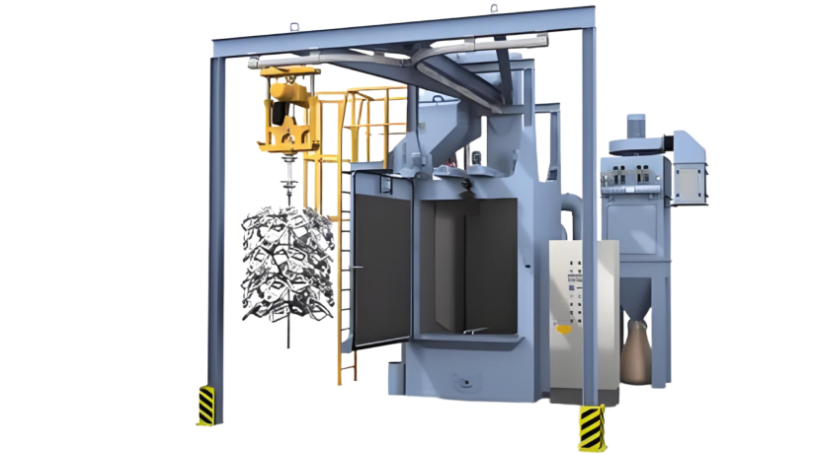

Single Hook Design

Hanger Shot Blasting Machine

Max lifting height: 0.5t-1.0t

Total blasting capacity: 180kg*27.5kW*2 ~ 240kg*211kW-7.5*2

Suitable for structural parts, deburring of die-casting parts and homogenization or hardening of dynamically stressed parts.

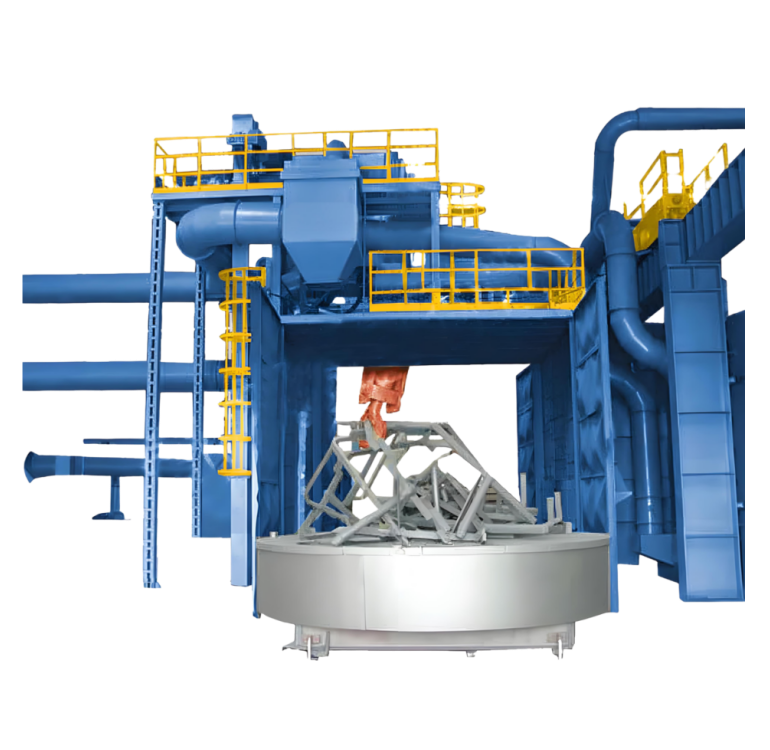

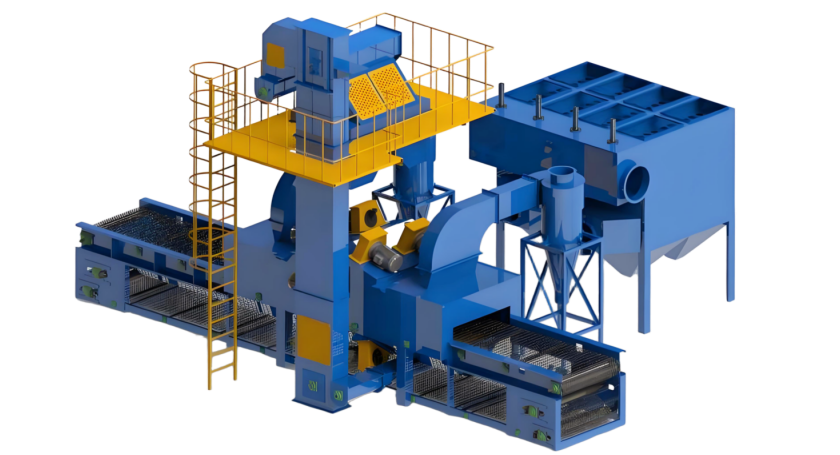

2-4 Shot Blasters

Catenary Shot Blasting Machine

Turning diameter: 1100-1500mm

Hook height: 1250-2100mm

Suitable for all-round shot blasting cleaning of large batches, cast steel, cast iron, and welded parts.

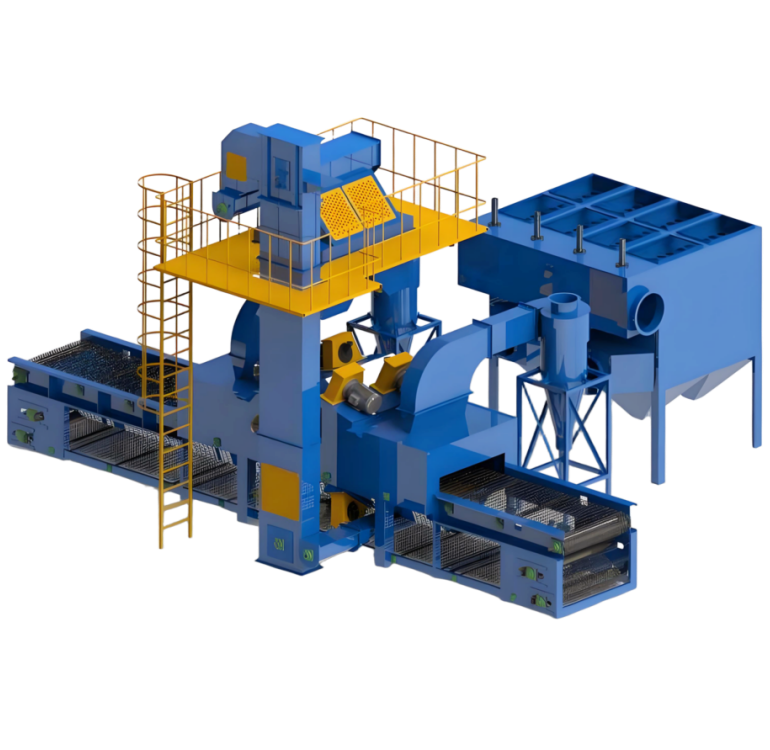

Continuous Production

Wire Mesh Shot Blasting Machine

Max workpiece width: 800-1250mm

Max workpiece height: 400-500mm

Suitable for sheet metal parts, die-casting parts, forging parts, and small and medium-sized and complex workpieces that are afraid of collision.

Automatic & Continuous

Rotary Table Shot Blasting Machine

Size of cleaning chamber: 1350*560mm~2654*560mm

Size of cleaning piece: 600*250*250~1000*500*250mm

Suitable for removing oxidized skin and foreign matter on the surface of crankshaft, mold and fixture, and collect and treat the dust generated.

Quality Cleaning for Small Pieces

Rotary Drum Shot Blasting Machine

Productvity: 0.6-1.2~3-5t/h

Feeding amount: 220-1000kg

Suitable for sand cleaning, rust removal, scale removal and surface strengthening of small castings, forgings, stamping parts, gears, springs and other parts

High Efficiency

Trolley Type Blasting Machine

Bogie Capacity: 5-50t

Workpeice dimensions: 2000*1000~5000*2000mm

Suitable for removing the molding sand, oxide scale, rust and dirt on the surface of the workpiece, eliminate the surface stress of the workpiece

For Many Materails Cleaning

Pass Through Shot Blasting Machine

Inlet width: 1600-4300mm

Inlet height: 550mm

Suitable for cleaning Steel Beam, just like H Beam, I Beam etc.

CUSTOMIZED SOLUTIONS OFFER

Customizable Shot Blasting Machine For Sale – For Specific Materials

SBMM specializes in developing customized shot blasting machines for unique materials and profiles, including springs, steel pipes, stone, wire, coil, rod, strip, and H-beams. Each machine is engineered to meet specific surface treatment requirements with precision and efficiency.

φ4-40mm

Steel Wire Shot Blasting Machine

The Wire Rod Shot Blasting Machine effectively removes scale, rust, and impurities from wire surfaces through high-speed abrasive projection, achieving a cleanliness level of Sa2.5 and surface roughness of Ra6.3–12.5μm. It offers an eco-friendly, cost-efficient alternative to chemical pickling while enhancing material durability.

Inner & Outer Wall Cleaning

Steel Pipe Shot Blasting Machine

The QG Series Shot Blasting Machine by SBMM efficiently cleans inner/outer surfaces of steel pipes and tubes, removing oxide scale and weld slag to reveal a uniform metallic finish. Its strategically positioned blast wheels and rotating workpiece feed ensure consistent, high-quality results across various pipe diameters, optimizing surfaces for painting and coating.

400-1000mm Workpiece Width

Steel Stripe Shot Blasting Machine

The steel strip shot blasting machine efficiently removes oxide scale, rust, and welding slag from strip surfaces through high-speed abrasive projection. It ensures high-quality cleaning (e.g., Sa2.5 standard), enhances surface adhesion for painting, and operates automatically with integrated dust collection for eco-friendly production.

300mm Spring Height

Spring Shot Blasting Machine

The Spring Shot Blasting Machine effectively removes scale and weld slag from steel springs of all sizes, revealing a clean metallic surface that enhances paint adhesion and coating durability through increased surface area. Custom designs are available for specialized spring configurations.

800-4000mm Cleaning Width

H Beam Shot Blasting Machine

The H beam Shot Blasting Machine efficiently removes rust, scale, and contaminants from metal profiles and sheets, serving industries like automotive, shipbuilding, and bridge construction. Customizable in cleaning width (800–4000mm) and conveyor speed (0.5–4 m/min), it features PLC control (Siemens/Omron) and a high-efficiency dust collection system, complying with CE standards for global market access.

45-55t/h Capacity

Anchor Chain Shot Blasting Machine

Specifically engineered for marine-grade chains, our Anchor Chain Shot Blasting Machine effectively removes rust, scale, and surface contaminants to achieve a uniform, glossy metal finish. This process significantly enhances coating adhesion and corrosion resistance, extending the service life of anchor chains in harsh environments.

500-5000kg Weight Range

Wheel Rim Shot Blasting Machine

The Wheel Rims Shot Blasting Machine efficiently removes rust, paint, and contaminants from alloy wheels through high-speed abrasive projection, achieving optimal surface roughness for enhanced coating adhesion. Its automated PLC-controlled system ensures thorough, eco-friendly cleaning with minimal abrasive waste and energy consumption.

APPLICATION

Wide Usages of Our Shot Blasting Machine

Automotive Manufacturing

Our shot blasting machines significantly enhance the fatigue resistance of critical parts like engine blocks and gears, ensuring longer service life and improved safety for vehicles

Shipbuilding Corrosion Protection

We provide efficient rust removal and surface preparation for ship hulls and decks, offering robust corrosion resistance to withstand harsh marine environments

Structural Steel Cleaning

Our equipment effectively removes rust and mill scale from large steel structures and bridges, ensuring optimal surface quality for extended durability and coating adhesion

Casting Defect Removal

Your foundry operations benefit from our machines’ ability to thoroughly clean castings by removing sand, scale, and imperfections, readying them for quality inspection

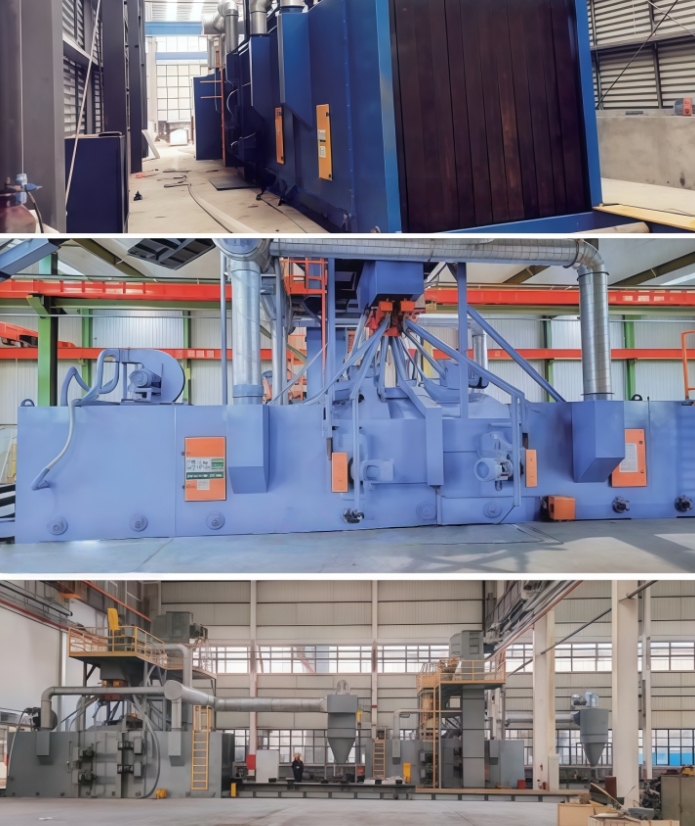

Direct-Coupled Shaft High-Power Shot Blasting Machine – Independently Developed, Invention Patent

The Heart of the Machine

- Independently innovatively developed, with performance close to that of German products.

- Patent No.: ZL201520702933.5

- Engaged European shot blasting experts for professional guidance.

- Adopt German dynamic balancing machine for detection.

- Adopt high-quality Siemens motors.

- Adopt Swedish SKF high-speed bearings.

- 25% higher efficiency than traditional belt-driven shot blasting machines.

- Maintenance costs reduced by 50%.

- The shot blasting speed is always constant, and the quality of cleaning and strengthening is stable.

MANUFACTURING DETAILS

why OUR PRODUCTS LEAD THE WAY

Advanced Patented Blast Technology

SBMM integrates proprietary systems like the direct-shaft blast wheel (patent-protected), ensuring 30% higher efficiency and 50% lower maintenance versus traditional belt-driven models, with precision abrasive targeting for consistent results

Smart Automation & Control

Our machines feature AI-driven PLC systems that auto-adjust parameters, reduce setup time by 50%, and enable remote monitoring for minimal downtime and optimized operations

Eco-Friendly & Low-Cost Operation

Equipped with multi-stage dust collectors (99.9% filtration) and abrasive recycling up to 99%, SBMM machines slash energy use by 60% and cut waste, aligning with global environmental standards like CE and ISO

Robust Build for Heavy-Duty Use

Constructed with high-chromium wear parts (e.g., 20,000-hour lifespan), manganese liners, and modular designs, our machines endure harsh conditions while reducing long-term ownership costs

Customization for Diverse Applications

From springs, pipes, and H-beams to wire rod and strips, SBMM offers tailored solutions with adaptable blast patterns and conveyor speeds, ensuring optimal performance for any material or industry

Global Support & Certified Quality

Backed by ISO, CE, and TÜV certifications, SBMM provides worldwide service networks, rapid spare parts delivery, and on-site technical support to maximize uptime and customer satisfaction

95% Precision Blasting Efficiency

SBMM’s direct-shaft blast wheel ensures 95% of abrasive hits target areas directly, drastically reducing abrasive waste and processing time compared to conventional systems。

20,000-Hour Component Lifespan

Engineered with premium wear-resistant materials and balanced designs, critical components like motors and liners operate reliably for over 20,000 hours, minimizing downtime and maintenance costs.

50% Lower Abrasive Consumption

Advanced abrasive recycling systems achieve 99% reuse rates, cutting material consumption by half compared to standard machines requiring higher flow rates for similar results

60% Energy Reduction with Smart Operation

Optimized motor and airflow designs reduce power usage by up to 60% versus traditional models, lowering operational expenses and environmental impact

ADVANCED EQUIPMENT MANUFACTURING

THE Complete WORK flow in our factory

SBMM integrates R&D, production, sales, and after-sales to deliver customized shot blasting solutions with direct factory quality and pricing.

STEP

01

Order Confirmation & Customization

Upon receiving inquiries, our engineering team collaborates with clients to define specifications, including machine type, blast wheel capacity, abrasive recycling systems, and material compatibility. Using 3D modeling and simulation tools, we validate design feasibility and provide detailed proposals with technical drawings and performance guarantees.

STEP

02

Welding

Our R&D team employs CAD/CAE software and German-engineered components to develop robust machine structures. Key features include high-chromium blast wheels, Mn13 wear-resistant liners, and PLC-controlled systems. Designs are optimized for energy efficiency and adaptability to client needs, such as custom chamber sizes and IoT-enabled monitoring.

STEP

03

Precision Manufacturing & Assembly

Components are fabricated using laser cutting and CNC machining for accuracy. Assembly integrates modular subsystems: blast chambers with reinforced Mn13 steel, centrifugal wheels with dynamic balancing, and automated abrasive recycling systems. Each unit undergoes inline quality checks.

STEP

04

Quality Testing & Delivery

Pre-shipment, machines are tested under load conditions to validate performance metrics such as blast uniformity (95% coverage), noise levels (<85 dB), and dust emission compliance (<10mg/m³). Clients receive certification reports and operational training. Finally, equipment is packaged for secure global logistics, with documentation for seamless customs clearance.

WORKING PRINCIPLE

Shot Blasting Machine Working

A shot blasting machine utilizes a high-speed rotating impeller (blast wheel) to centrifugally propel abrasive media—such as steel shot, grit, or cut wire—against the surface of a workpiece. This process removes contaminants (rust, scale, old coatings, burrs) and simultaneously creates a uniform surface profile essential for coating adhesion. The machine operates via a closed-loop system where abrasive media is continuously recycled, dust is filtered, and cleaned media is reintroduced for repeated use.

Key Operational Stages:

- Abrasive Acceleration: Electrically driven blast wheels (often double-disc designs for stability) accelerate media to high speeds (e.g., 80 m/s). The impeller’s design ensures concentrated and uniform impact distribution, maximizing efficiency and reducing energy consumption.

- Workpiece Handling and Exposure: Workpieces are transported via conveyors (roller, belt, or trolley systems) or rotated (e.g., turntables, tumble baskets) within the blast chamber to ensure multi-angle, complete exposure to the abrasive stream. This is critical for complex geometries and high-volume processing.

- Surface Treatment and Impact Effects: The high-kinetic-energy impact cleans surfaces to standards like Sa2.5 (near-white metal cleanliness) and achieves specific roughness profiles (e.g., Ra6.3–12.5μm). Additionally, it induces compressive stress through shot peening, enhancing fatigue strength and resistance to micro-cracking.

- Media Recovery and Reclamation: Spent media and debris fall through grated floors into a collection system. Screw conveyors transport the mixture to a bucket elevator, which lifts it to a cyclonic separator. Here, reusable media is separated from dust and broken abrasives (efficiency ≥99.5%), ensuring only optimal media returns to the blast wheel.

- Dust Extraction and Environmental Control: Integrated dust collectors (e.g., pulse-filter systems) capture fine particles and pollutants, maintaining air quality and compliance with environmental standards (e.g., dust emissions <10mg/m³). This step is vital for operator safety and equipment longevity.

Advanced Features in Modern Machines:

- PLC Automation: Systems use programmable logic controllers (e.g., Siemens/Omron) for precise control over parameters like conveyor speed, blast time, and media flow, ensuring repeatability and reduced manual intervention.

- Energy Efficiency: Direct-drive blast wheels (vs. belt-driven) reduce power consumption by 10–15% while maintaining high blast capacity (16–20 kg/min·kW).

- Customization: Machines are tailored for specific applications (e.g., H-beams, springs, gas cylinders) with adjustable blast patterns, chamber sizes, and handling systems.

This refined process highlights precision, sustainability (via media recycling and dust control), and adaptability to industrial needs, making shot blasting critical for sectors like automotive, aerospace, shipbuilding, and structural steel fabrication.

MATERIALS & CHOOSING GUIDE

Applicable Materials of Shot Blasting Machine

Shot blasting machines are highly versatile surface treatment systems capable of handling a wide range of materials, primarily various types of metal products and components. Here’s a breakdown of commonly processed materials and workpieces:

•Various Metal Abrasives and Media: The cleaning process itself utilizes a variety of abrasive media, which are selected based on the material of the workpiece and the desired surface finish. Common abrasives include steel grit, copper shots, aluminum pellets, stainless steel shots, wire cut shots, as well as non-metallic options like silica sand, glass beads, and even synthetic materials such as sodium bicarbonate (baking soda) .

•Structural Steels: This is a primary application. Shot blasting is extremely effective for cleaning and preparing H-beams, I-beams, steel plates, steel pipes, and other structural components used in construction, bridges, and heavy machinery . It removes mill scale, rust, and weld slag, creating an ideal surface for painting or coating.

•Castings and Forgings: The process is well-suited for cleaning large castings, forgings, and welding parts by removing sand, oxide scale, and other surface impurities from the manufacturing process . This helps in improving the surface quality and preparing them for further use or inspection.

Advanced Features in Modern Machines:

This refined process highlights precision, sustainability (via media recycling and dust control), and adaptability to industrial needs, making shot blasting critical for sectors like automotive, aerospace, shipbuilding, and structural steel fabrication.

CASE STUDIES

Shot Blasting Machine Exported Cases

Rubber Type

Shot Blasting Machine in Dubai

Crawler Type

Shot Blasting Machine in MALAYSIA

Chain Type

Shot Blasting Machine TO UAE

Double Hook

Shot Blaster DELIVERED TO Kenya

Cantenary Type

Shot Blasting Machine In Ecuador

Hook Type

Shot Blasting Machine In Liberia

SBMM Shot Blasting Machine Exported to All Over the World

Projects Completed

890+

Countries Exported

70+

Machines Sold

2500

Company Cooperated

50+

CUTOMIZED SOLUTIONS OFFERED

We Offer Tailor-made Solutions to Meet Your Projects Needs

As a leading manufacturer of industrial shot blasting equipment, SBMM combines 30 years of engineering excellence with cutting-edge German-American technologies to deliver high-performance surface treatment systems. With 3 national patents and 65+ utility innovations—including Asia’s exclusive 75kW direct-drive blast wheel—we empower industries from automotive to nuclear energy with 25% higher efficiency and 50% reduced maintenance.

SBMM specializes in bespoke solutions tailored to unique industrial demands. We collaborate closely with clients to develop application-specific machines—from nuclear valve blast systems for power plants to automated H-beam processors for structural steel fabrication.

32k

Loved Our Machine

“SBMM’s shot blasting system boosted our productivity by 30% while reducing abrasive consumption. “

Alva Edision

– From Australia

“Their customized H-beam machine eliminated rust and scale effortlessly, cutting our preparation time by 50%. “

Salome Gericke

– From Namibia

“SBMM’s energy-efficient design slashed our power costs by 25%, and the 99% abrasive recycling minimized waste. “

Kangogo Stanley

– From Kenya

“The PLC-controlled automation ensured flawless surface profiling for turbine blades, meeting Sa2.5 standards consistently. “

Anic Kashasha

– From Tanzania

Factory Direct Sale

Experience factory-direct pricing and customized solutions with SBMM shot blasting machines. Enjoy faster delivery, higher quality control, and significant cost savings by eliminating intermediaries. Submit your inquiry in the form to get a personalized quote today!

Get A Free Quote Now

WE OFFER CUSTOMIZED SOLUTIONS FOR YOUR DEMANDS

TALK TO OUR EXPERTS TO GET YOUR SOLUTIONS

Zhengzhou City, Henan Province, China

Business Hours

Weekday

00:00 – 24:00

Weekend

00:00 – 24:00